Nanomaterials and Separation Technologies

Materials science and engineering provides a cornerstone for many interdisciplinary research and application areas. With the emergence of nanotechnology, new approaches have been introduced to modify catalysts and tailor surface chemistries. These techniques offer alternative solutions to existing catalysis, separation and surface science problems, while allowing us to study the relevant fundamentals in a different context. Our group focuses on designing and synthesizing functional nanoscale particles for targeted applications to further develop and gain deeper understanding of modern catalysis, separation and drug delivery. Ongoing research topics are described as follows.

Membrane materials and processes for industrial waste water treatment

We address challenges associated with complex water chemistries, different reuse standards, and economics by integrating catalytic nanoparticles into commercial membranes that can decompose dissolved organic compounds (DOC) into water and carbon dioxide without the need to identify the DOC.

Molecular Separation Methods for Ionic Liquids Recycling from Carbon Feedstock

Given the high cost of most ILs, the recovery/recycling of ILs will be a crucial component of extracting valuable fuels/chemicals from carbon feedback, especially for industry-scale operations. Collaborating with national laboratory partners, separation/recovery processes will be assessed and selected using existing and to-be-developed understanding of molecular weight range and crystal structures of extracted compounds of carbon feedback. Information on extract crystalline structure will provide insight on which separation technology/process is optimal.

Hydrogel nanoparticles for the encapsulation and delivery of diagnostic and therapeutic molecules

Polyethylene glycol (PEG) hydrogel-based nanoparticles are a compelling delivery vehicle because they can be far more easily designed and tuned to specific therapeutic needs than existing materials. However, there exist no reliable methods to prepare PEG particles on nanometer length scales with narrow size distributions and well-defined loading. We employ a microfluidic processing approach to address this challenge to take advantage of its exquisite control over particle size and uniformity and facile tunability of the macromolecular network.

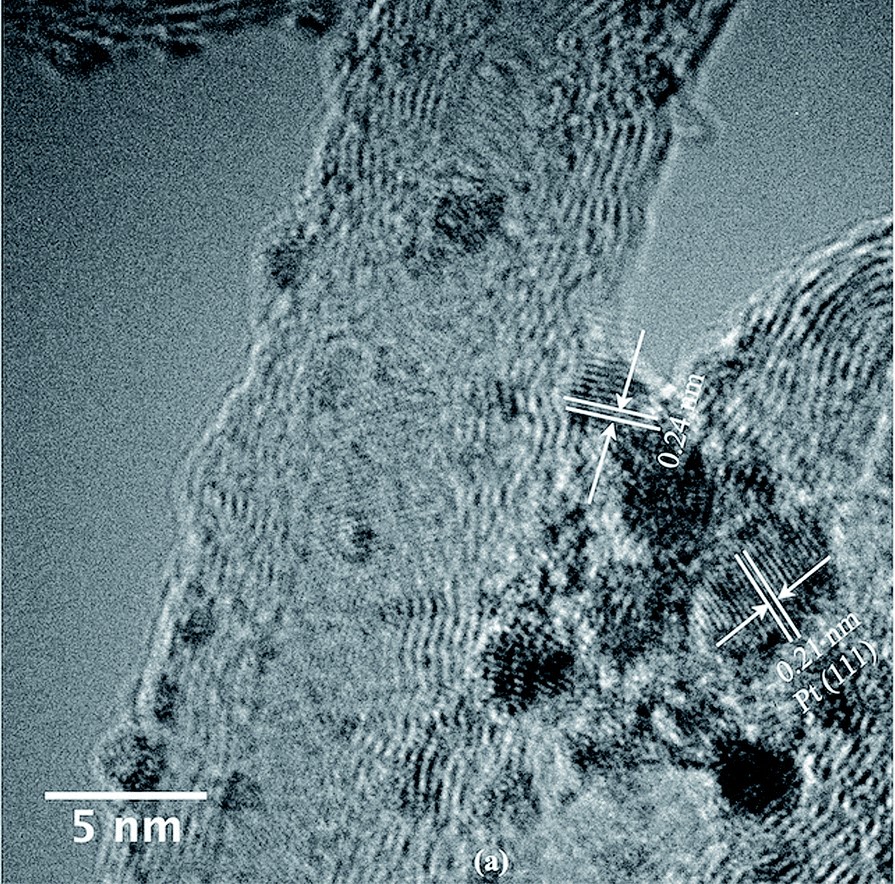

Bottom-up design and synthesis of nanocatalysts via atomic-level surface modification

The catalyst platform we have built consists of nano-scale, phase-pure transition metal carbide (TMC) supports and metal nanoparticles (< 3 nm) deposited by vapor phase atomic layer deposition (ALD). Taking advantage of the atomic level control of deposited metal nanoparticles, we aim to probe the synergetic effect between supported metal catalysts, such as platinum, and underlying TMC supports, via surface characterization and device performance. Such understanding helps further reduce noble metal catalyst loading in applications including fuel cells and, more importantly, sheds light on future catalyst designs that enable replacing noble metal catalysts with more economical catalysts such as TMC.

Nanoscale rare earth element (REE) catalysts

The central hypothesis that motivated this area of study is that unique morphology and reduced size may enhance catalytic activity of REE-based catalysts, such as lanthanide oxysulfides/oxysulfates, without compromising their unique sulfur tolerance. In addition, the reduced size may allow an alternative membrane reactor configuration (a.k.a. catalytic composite membrane micro-reactors, or CMMR), which may further increase catalyst activity and durability, while beneficially shifting equilibrium toward product generation.

Sponsors of our research include: Department of Energy (DOE) Basic Energy Sciences (BES), Wyoming National Science Foundation (NSF) Experimental Program to Stimulate Competitive Research (EPSCoR), University of Wyoming School of Energy Research (SER), Wyoming NASA Space Grant Consortium, University of Wyoming